During the existence of LLC “RDE “Factory of MDU” it has made more than 80 degassing units of the type MDU, consisting of 147 vacuuminng modules, where are operated 272 pumps. For the period from September 2010 to June 2014 over 4975000000 m3 methane-air mixture is pumped out from coal seams with degassing units of the type MDU.

LLC “RDE “Factory of MDU” offers you two ways of methane utilization:

Cogeneration units

Cogeneration is a highly efficient method of production of heat and electricity. The efficiency of electricity production in the classical power plants is in the range of 25 to 35%, while cogeneration units work with efficiency of 80 to 90% because of using of thermal energy.

The payback period of cogeneration units is from 2.5 to 3 years.

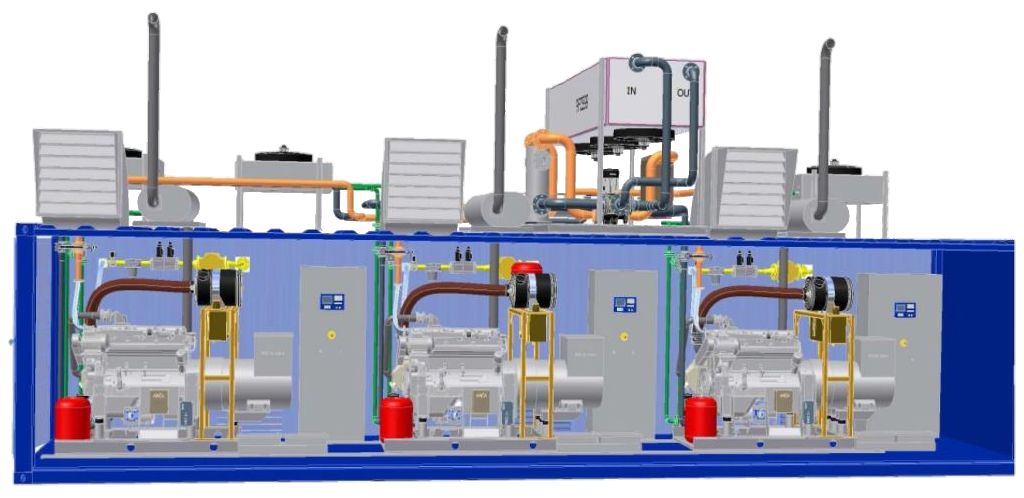

The unit is made as a modular construction, i.e. the engine, the generator and the rest of equipment (heat exchangers, fittings, silencer, etc.) are located on the common frame in the module of container type. All the units are equipped with control and measuring instruments (CMI), electric control and synchronization cabinet, power switchboard.

The advantages of modular construction:

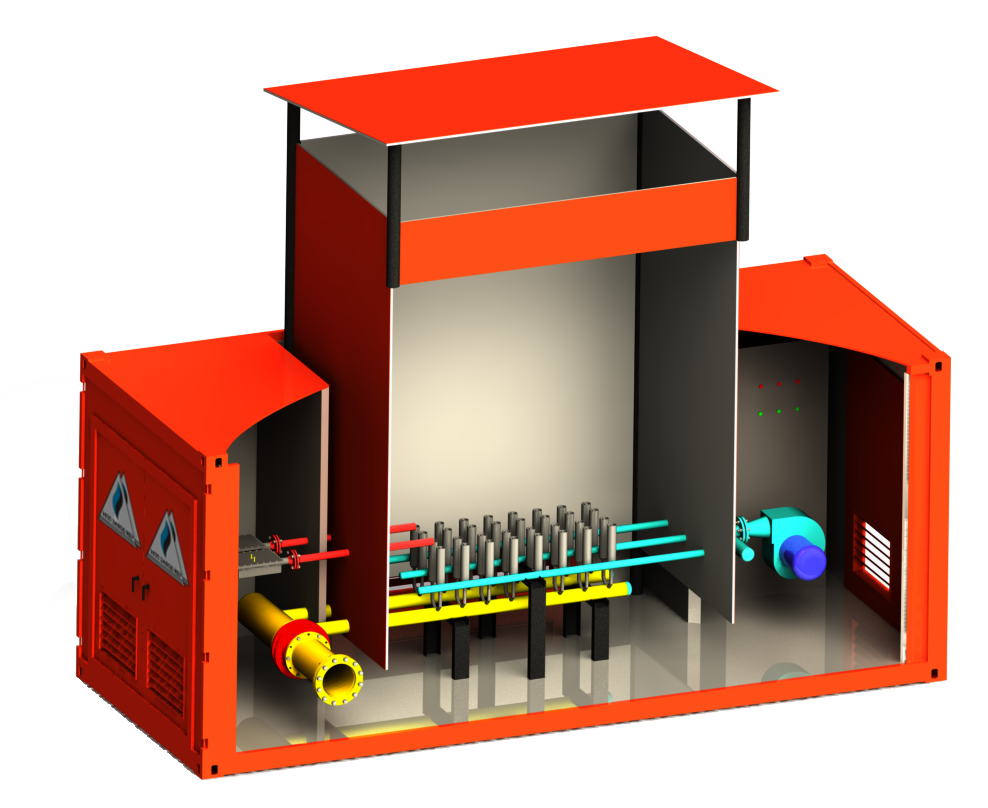

Flare unit of the closed type

Modular degassing units of the type MDU can additionally be equipped with a module of flaring and utilization, which is made as a flare of the closed type with possibility of heat utilization. Concentration of methane in flared methane-air mixture is in the range of 25-100%.

The advantages of module of flaring and utilization are:

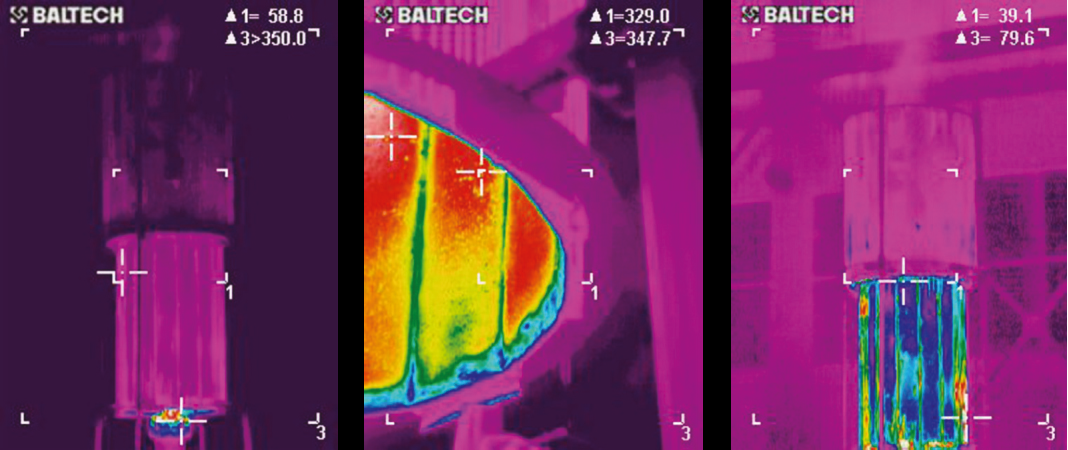

The heat insulating properties of a double-layer fire protection

The temperature at various spots of flare:

a) the temperature of burner devices to 350 degrees C.

b) the temperature of the inner wall is 347,7 degrees C.

c) the temperature of the outer wall is < 80 degrees C.